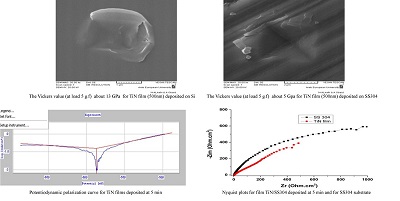

Morphology and Corrosion Behavior Study of Thin TiN Films Deposited at Different Substrates by DC Magnetron Sputtering

Published 2021-03-30

Keywords

- TiN film,

- DC magnetron sputtering,

- morphology,

- corrosion behavior

How to Cite

Abstract

TiN thin films have been deposited by magnetron sputtering (DC) method under pure argon (100% Ar) gas for different times at 100 oC temperature. Additionally, three substrate types have been used: Low Carbon Steel (LCS), Stainless Steel (SS304) and Silicon of (100) orientation. The composition of the films has been verified by Energy Depressive X-ray Spectroscopy (EDX) analysis for films deposited on Si substrate. This analysis has proved that the nitride films TiN was sub stoichiometry, Scanning Electron Microscope (SEM) image was used to estimate the thickness of TiN/Si film. X-ray diffraction (XRD) measurements were also applied to investigate the orientations of films. All the films (coated samples) have shown enhanced corrosion resistance compared with virgin SS304 and LCS substrate (noncoated sample) in 3.5% NaCl at 25 oC (equivalent to seawater). Morphological behavior was investigated by means of Atomic Force Microscopy (AFM), which indicates very smooth films and consequently related with corrosion resistance using Tafel and the electrochemical impedance spectroscopy (EIS) measurements. It was found the thinner film has revealed higher corrosion resistance and low roughness.