Published 2023-04-12

Keywords

- Anodization,

- Experimental Design,

- Wetting,

- Glycerin

How to Cite

Abstract

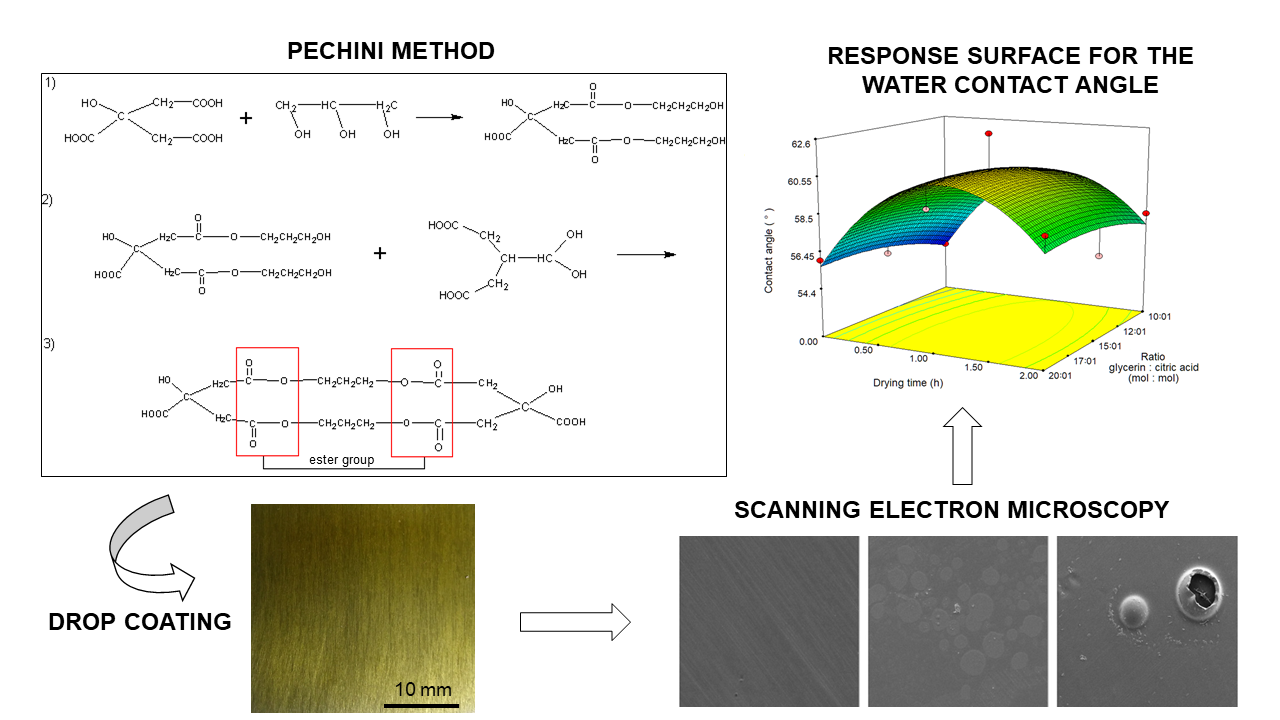

To fabricate a hydrophobic coating using the sol-gel method (Pechini), an experimental design using the drying time and chemicals ratio as variables was developed. The coating was deposited on an aluminum substrate (AA6061-T6) treated by acid solution or anodization method. The surface wettability was measured using a goniometric instrument. Coatings were fabricated using different numbers of layers, heating rates, and drying temperatures, and their morphologies were observed using visual analysis and scanning electron microscopy. The use of anodization treatment with a furnace ramp of 1 °C min-1, a drying temperature of 220 °C ± 10 °C, and single-layer application, produced a coating free of visible flaws and apparent damage. The coating was obtained with a 15:1 glycerin:citric acid ratio and sample pre-polymerization in the drying oven for 1 hour at 100 °C resulted in the highest contact angle, 62° ± 2°, which meets the ASTM D-7334-08 standard for a hydrophobic surface.